Page 2 of 5

Re: Surface scratch on the deck

Posted: Fri Apr 02, 2010 6:07 am

by icrman

It either looks like someone used something with a sharp point to remove the gasket, or layed it on that surface and debris of some sort did it when it was moved. Could have been a trainee at gasket scraping too.

Re: Surface scratch on the deck

Posted: Fri Apr 02, 2010 5:47 pm

by smh0101

Just a word about swapping stuff...

Now, I'm not sure if the massive difference in my built motor (2.5L) was due to the heads (ej25d) or the block (2001 RS block w/ CP Pistons and STi rods).... Either way... It was a high(er) compression ratio motor (9.1:1 I believe when I calculated it)

But the engine was a totally different animal. Wayyy more low end torque, instant spool (both vf24 and td04) and had quite a bit of top end to.

Ask Zach how it felt compared to stock. He rode in it and, Zach correct me if I'm wrong, was pretty impressed.

Something to think about. Not trying to convince you to do anything extra, but IMO its worth it, in the long run you'll save money because you wont HAVE to do it later. You can always turn down the boost for the tranny's sake.

Re: Surface scratch on the deck

Posted: Fri Apr 02, 2010 6:39 pm

by Legacy777

Thanks for the comments Spencer. I should be at 8.5:1 with the Wiseco's. If I go DOHC, I'd have to buy A LOT of stuff. Which is why I think I'm just going to stick with the 2.2 heads. Later down the road if I want big power, I'd consider going EJ257. With the Link, EM really isn't an issue.

Re: Surface scratch on the deck

Posted: Fri Apr 02, 2010 7:04 pm

by smh0101

Fair enough

Lucky... you've got a Link

haha

Re: Surface scratch on the deck

Posted: Mon Apr 05, 2010 6:26 pm

by Legacy777

Finished tearing down the motor this weekend. It's a shame....everything looked good. Pistons looked good, no blow by past the rings, bearings looked good. Oh well, those are the breaks. Will try and update with pictures tonight or tomorrow.

Re: Surface scratch on the deck

Posted: Tue Apr 06, 2010 3:51 am

by Legacy777

Ok, here's pics from this weekend and tonight. The main bearings looked alright. I'm going to plastigage them tomorrow. I will say, doing plastigage on a subaru motor is a pain.

I did the rod bearings tonight. They all seemed within in spec, all/most were around 0.0015". The STD spec 0.0010" - 0.0021". However, the rod bearings did not look near as good of condition as the main bearings. Not sure what's up with that. If you have any comments, let me know. I'm not sure what to do about the crank. If it needs to be polished, or if it's fine like it is. Let me know what you think about that.

On to the pictures

Saturday disassembly work

http://www.main.experiencetherave.com/s ... eadwork/05

Monday bearing clearance check

http://www.main.experiencetherave.com/s ... eadwork/06

Re: Surface scratch on the deck (Now with 100% more rebuild)

Posted: Tue Apr 06, 2010 4:14 am

by Legacy777

I've talked with Dan a little on bearings. He had recommended Calico coated bearings. They're currently showing everything on backorder. I need to call them, but was curious what others thoughts were. I know the Calicos are just coated ACL bearings....they any better than OEM stuff?

Thanks

Re: Surface scratch on the deck (Now with 100% more rebuild)

Posted: Tue Apr 06, 2010 10:00 pm

by Legacy777

I checked the main bearing clearances this morning, and they all are around 0.0015". The std spec calls for 0.0004" - 0.0012" with a service limit of 0.0016" on main's 1 & 5, and 0.0014" on main's 2, 3, & 4. The plastigage I had was only rated to read down to 0.001". So I'm not sure if the fact they're off is a big deal or not, or just possibly a measurement issue. There's some spots on the crank journals that could probably be better, but just not sure what's acceptable or not. I'd guess since the mains looked ok, those clearances probably aren't too big a deal.

Here's pictures

http://www.main.experiencetherave.com/s ... adwork/07/

Re: Surface scratch on the deck (Now with 100% more rebuild)

Posted: Wed Apr 07, 2010 12:40 am

by gijonas

Looks to me like you have some nicely broken in parts ready to go.

Re: Surface scratch on the deck (Now with 100% more rebuild)

Posted: Thu Apr 08, 2010 1:51 am

by Legacy777

I called ACL this morning, and they said their race bearings are not any softer. They use the same tri-metal material. The race bearings have a harden metal backing to provide additional support and keep them in place.

So I'm go to go with the ACL race bearings and have them coated by Calico.

Talked to Matt M about my crank. He said the journals look a little worse for wear, but I tend to agree with. So I think I'm going to try and find a used crankshaft in better shape. The turbo and non-turbo ej22's used the same crankshaft, so I should be able to find one that's in a little better shape than mine.

Re: Surface scratch on the deck (Now with 100% more rebuild)

Posted: Mon Apr 12, 2010 2:23 am

by Legacy777

Here's pics of the Subaru gasket kit, Eagle rods, & Wiseco pistons.

http://www.main.experiencetherave.com/s ... adwork/08/

Re: Surface scratch on the deck (Now with 100% more rebuild)

Posted: Mon Apr 12, 2010 3:35 am

by ericem

That looks like fun. I think I am going to bring my ej22T in my garage to my basement and start taking it apart

Re: Surface scratch on the deck (Now with 100% more rebuild)

Posted: Tue Apr 20, 2010 11:55 pm

by Legacy777

Got the calico coated ACL race bearings and ARP studs

http://www.main.experiencetherave.com/s ... adwork/09/

Question, do those ARP studs look like the right ones? I guess all the pictures I've seen of them, they are black, not chrome.

Re: Surface scratch on the deck (Now with 100% more rebuild)

Posted: Sun May 23, 2010 9:43 pm

by Legacy777

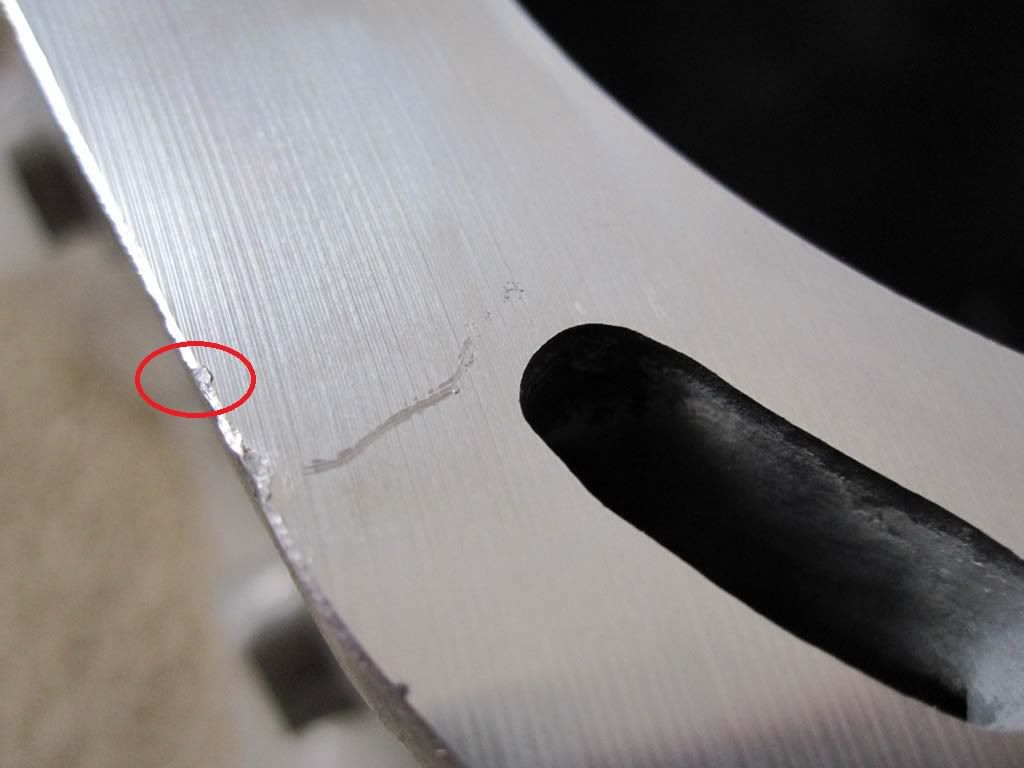

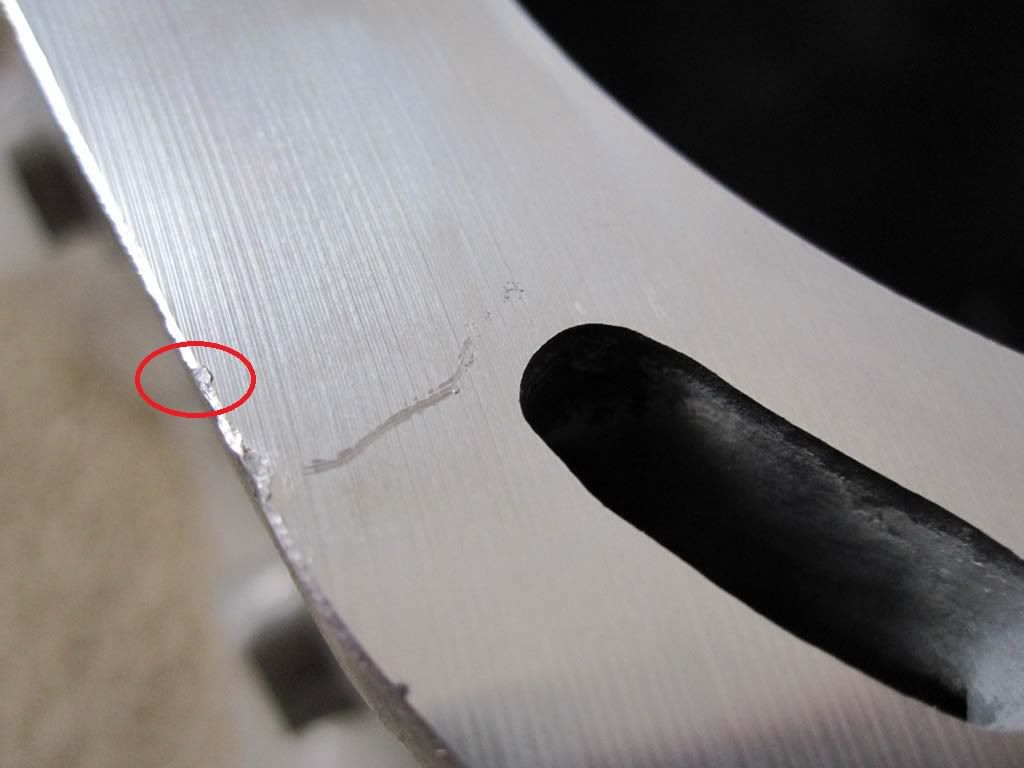

Well I had gotten the motor back from the machine shop several weeks ago, but other things were pressing and I hadn't done anything with it. This weekend I cleaned the block and several other parts.......and I really can't seem to get a break with this damn thing. I'll save you the other parts BS....but upon inspection of the block....there's ANOTHER scratch on the deck!!!

This one is out near the edge. It looks like it goes through where the coolant passage part would seal. I would feel more comfortable with using some sealant or copper gasket around this one. But I don't know.....just kind of pissed off....

Here's pics

http://main.experiencetherave.com/subar ... eadwork/10

Re: Surface scratch on the deck (Now with 100% more rebuild)

Posted: Sun May 23, 2010 11:01 pm

by gijonas

Dude those scratches are so minor,especially the new one.Thats nothing a conditioning wheel wont make disappear.And there are more pressing things to focus worry upon.

Re: Surface scratch on the deck (Now with 100% more rebuild)

Posted: Sun May 23, 2010 11:06 pm

by Legacy777

I would tend to agree with you.....the new one is not very deep. I'll probably try a conditioning wheel.

I'm just cranky.......

Re: Surface scratch on the deck (Now with 100% more rebuild)

Posted: Mon May 24, 2010 2:08 am

by 93forestpearl

That folded aluminum up from that is more of an issue than the scratch. Buss the scratch the the edge, and use some copper gasket spray.

Re: Surface scratch on the deck (Now with 100% more rebuild)

Posted: Mon May 24, 2010 2:14 am

by Legacy777

93forestpearl wrote:Buss the scratch the the edge, and use some copper gasket spray.

Did you mean buff the scratch to the edge?

Should I use the copper gasket spray on the entire thing, or just that area?

Re: Surface scratch on the deck (Now with 100% more rebuild)

Posted: Mon May 24, 2010 4:39 am

by 93forestpearl

That fap of material.

If you use copper spray, do the whole gasket, front and back. Ron at Axis/Raw even recommends it on his $15k shortblocks.

Re: Surface scratch on the deck (Now with 100% more rebuild)

Posted: Mon May 24, 2010 4:50 pm

by Legacy777

Ok....I'll have to get rid of that chunk of material.

Any particular type of copper gasket spray you/they recommend?

Thanks

Re: Surface scratch on the deck (Now with 100% more rebuild)

Posted: Mon May 24, 2010 9:38 pm

by 93forestpearl

I believe Permatex is the standard.

Re: Surface scratch on the deck (Now with 100% more rebuild)

Posted: Mon May 24, 2010 10:04 pm

by gijonas

Yeah,the permatex copper spray is pretty sweet.Just treat it as like a copper colored spray paint for both sides of your gaskets.I do a few coats until it looks like it is consistent,it wont seem to cover all that well the first coat.

Re: Surface scratch on the deck (Now with 100% more rebuild)

Posted: Tue May 25, 2010 4:11 am

by Legacy777

Good deal.

Thanks guys!

Re: Surface scratch on the deck (Now with 100% more rebuild)

Posted: Tue Jun 01, 2010 3:54 am

by Legacy777

Ran into more issues this weekend. I really wanted to get the motor together.

The first issue was that the machine shop boogered up one of the guide pins on the block. So the two block halves would not fit together. I will probably just go ahead and replace all the guide pins. This isn't a huge problem, but another set back.

The second issue was that when checking the bearing clearances on the rods, they appear to be too small. I need to double check, but what I was showing was less than 0.001". I need to get some better plastigauge that reads smaller tolerances. If that's really the tolerances, I'm not sure what to do other than to have the journals polished down a little bit. The journals were in spec. So the only thing I can think of is the ACL bearings with the Calico coating is too thick. So I'd hate to polish down a good crank journal......grrrr

Here's some misc. pictures from Saturday's work. I was going to put the motor together in the living room to keep everything clean and dust free....that didn't work out the way I planned

http://main.experiencetherave.com/subar ... eadwork/11

http://main.experiencetherave.com/subar ... eadwork/11

Re: Surface scratch on the deck (Now with 100% more rebuild)

Posted: Tue Jun 01, 2010 4:24 am

by Legacy777

Well I don't see the block half pins in the parts book. So I may have to try and find something somewhere else.....